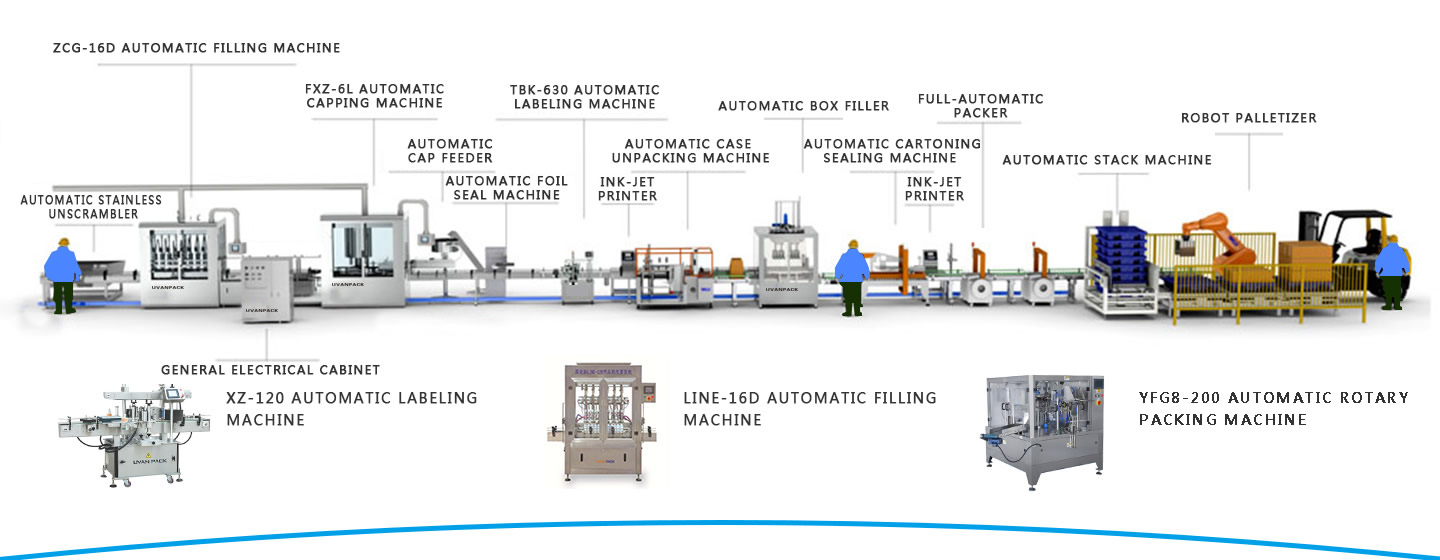

Features of performance:

1. Mitsubishi PLC, touch screen-based human-computer interface, variable-frequence governor and other systems are adopted; in this way, the speed can be adjusted freely and easy, stable operation is ensured;

2. Cutting-edge fault detector: When the working air pressure is abnormal or the heating pipe breaks down, alarm will be sent;

3. Imported plastic bearings are partially used; there is no need to add oil, which reduces pollution to materials;

4. Imported vacuum generator is used directly, which avoids pollution to the production environment;

5. Comply with the health standard of the food processing industry. The parts and components on the machine that will contact the materials and the packing bag shall be made of stainless steel or processed by other materials in conformity with the food sanitary standard in order to ensure the sanitation and safety of food;

6. Wide range of packing: By choosing different measuring plugging instruments, it is applicable to the packing of liquid, paste, particles, powder, irregular lumps, etc.

7. The sophisticated spiral film forming technology automatically finishes bag making, measurement filling, sealing and other packing processes, which further saves production cost.

8. Wide range of application:Application to multilayer composite film, single-layer PE and PP and other materials; capable of packing flat pouch, triangle sealing bag, four-edge sealing bag and other shapes of bag;

Parameter:

|

Model |

Dimension and scope of bag |

Packing capacity |

Packing speed

|

Power |

Gas consumption |

Dimension of equipment |

Weight |

Function |

|

YF-110 |

50mm×50mm(Min)

110mm×130mm(Max) |

60ml |

40-80ppm |

2kw |

N/A |

2200mm(L)

940mm(W)

1250mm(H) |

520kg |

Three side sealing, four side sealing |

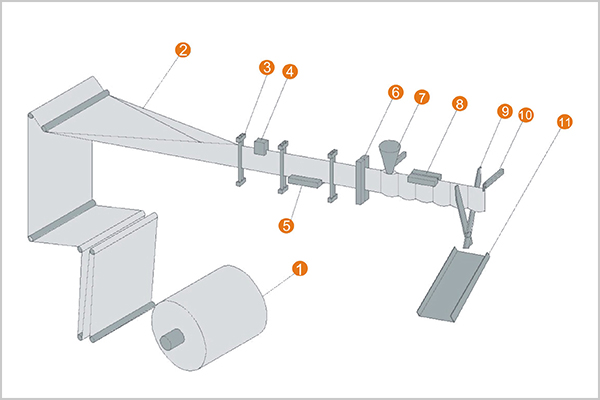

Technology: